Food & Beverage Projects

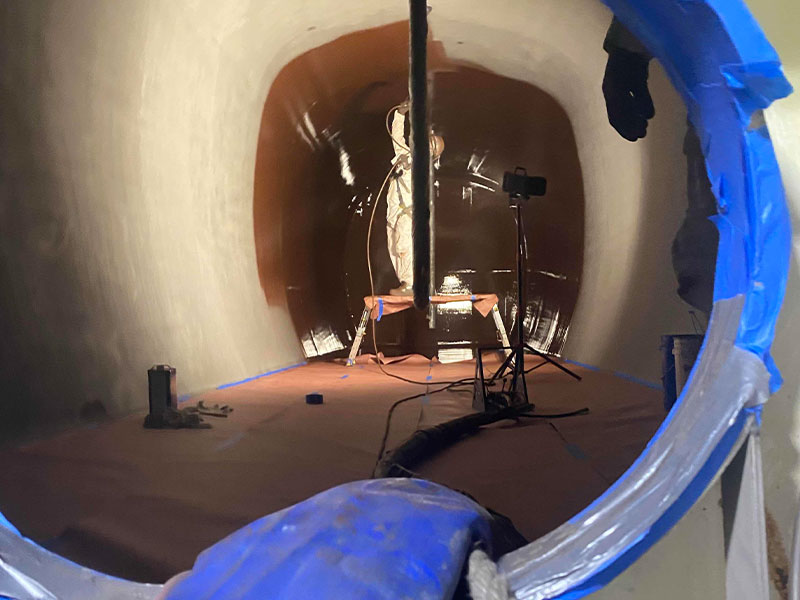

Brewery Vessel Restoration

Yuengling Brewing • Pottsville, PA

Beverage Manufacturing

Project Overview: Yuengling Brewing, America’s oldest brewery, required a comprehensive restoration of their beer vessels to maintain production efficiency and product integrity. As part of their commitment to quality, they partnered with Niles Industrial Coatings and Sherwin-Williams to perform an extensive internal and external coating application.

Scope of Work

- Internally blasted vessels to an SSPC-SP10 blast profile to ensure optimal adhesion.

- Applied stripe coating followed by two coats of Munkadur coating using a heated plural component pump for enhanced durability.

- Completed abrasive blasting and re-coating of the interior and exterior of 9 beer vessels within 30 days, minimizing downtime for Yuengling’s operations.

Results & Benefits

✔ Improved vessel longevity and protection from corrosion

✔ Enhanced product safety through high-quality coating applications

✔ Minimal production downtime with efficient 30-day turnaround

✔ Industry-compliant surface preparation and coatings

Partner With Us for Your Next Project

If your facility requires specialized coatings or restoration services, Niles Industrial Coatings can help. Our expertise in tank restoration, safety coatings, and facility maintenance ensures long-term reliability for your operations.

Spill Containment Tank Repair

Mead Johnson • Zeeland, MI

Baby Food Manufacturing

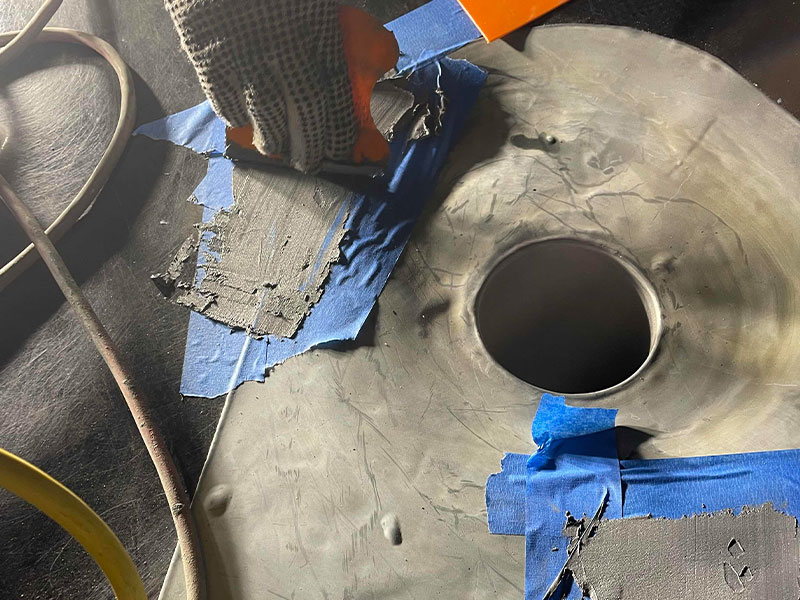

Project Overview: Mead Johnson, a leading baby food manufacturer, needed critical tank liner repairs for their spill containment system. To maintain strict safety and compliance standards, they partnered with Niles Industrial Coatings to restore their containment infrastructure efficiently and effectively.

Scope of Work

- Performed tank liner repairs to restore containment integrity.

- Ensured the system met food safety and environmental regulations.

- Completed project with minimal disruption to operations.

Results & Benefits

✔ Enhanced containment reliability for safe operations.

✔ Compliance with regulatory requirements for food-grade facilities.

✔ Preventative maintenance measures to extend equipment lifespan.

Lead Paint Removal & Containment

Kellogg • Battle Creek, MI

Food Processing

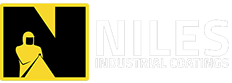

Project Overview: Kellogg’s facility in Battle Creek required lead paint containment and removal to ensure safety in their process areas. The work needed to be completed without interrupting production while meeting strict environmental and health standards.

Scope of Work

- Contained areas of delaminating lead paint in high-risk zones.

- Hand tool removal of lead paint from ceilings in sensitive production areas.

- Executed project with zero impact on manufacturing operations.

Results & Benefits

✔ Improved facility safety and compliance with lead abatement standards.

✔ Non-invasive execution without halting production.

✔ Prolonged structural integrity of process areas.

Interior Protection & Lead Abatement

Coors • Albany, GA

Beverage Manufacturing

Project Overview: To maintain a safe and clean production environment, Coors partnered with Niles Industrial Coatings to perform lead abatement and interior protection in their facility. The project required careful execution to preserve production integrity while ensuring worker safety.

Scope of Work

- Completed lead abatement in critical interior spaces.

- Applied protective coatings to safeguard facility infrastructure.

- Ensured compliance with industry safety regulations.

Results & Benefits

✔ Health and safety compliance for facility workers.

✔ Extended durability of interior surfaces.

✔ Minimized environmental impact through controlled abatement.

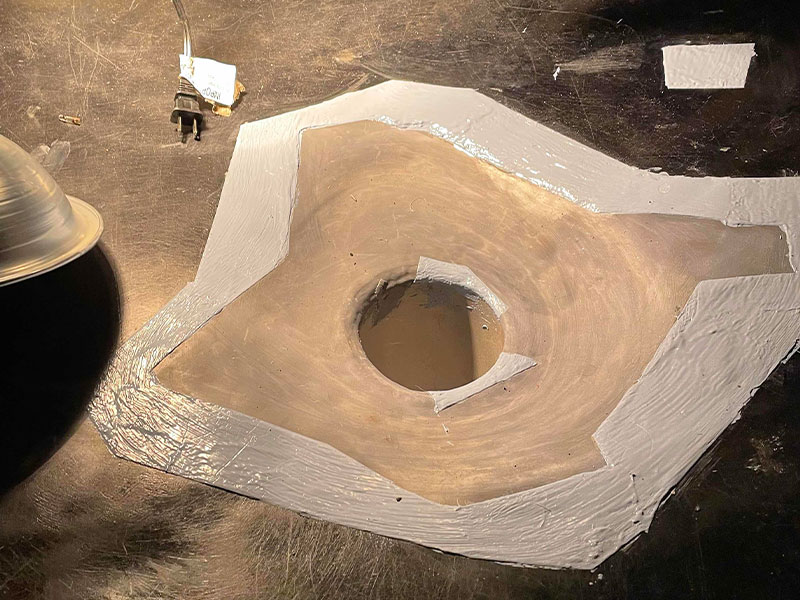

Food-Grade Coating Application

Conagra • Oakdale, CA

Food Manufacturing

Project Overview: Conagra needed a high-performance food-grade coating solution to maintain the longevity of its juice storage tanks and tomato paste vessels. Niles Industrial Coatings provided a seamless restoration that ensured compliance with food safety standards.

Scope of Work

- Internally blasted vessels to an SSPC-SP10 blast profile.

- Applied 2 coats of Munkadur coating using a heated plural component pump.

- Completed restoration of four juice storage tanks (inverted cone-shaped) and tomato paste vessels.

- Sandblasted old coatings and applied new food-grade lining.

Results & Benefits

✔ Enhanced corrosion resistance for extended equipment lifespan.

✔ FDA-compliant coatings for food safety assurance.

✔ Efficient project completion with minimal operational downtime.

Tank Repairs & Surface Restoration

Anheuser-Busch • Columbus, OH

Beverage Manufacturing

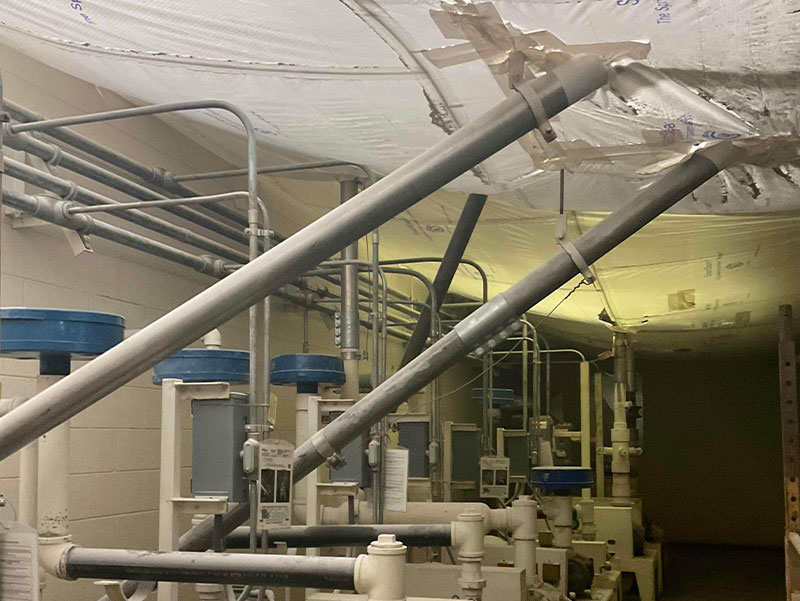

Project Overview: To maintain the integrity of their storage tanks, Anheuser-Busch required professional tank repairs and surface restoration. The project focused on cleaning, repairing, and recoating critical tank surfaces to prevent future degradation.

Scope of Work

- Performed SSPC SP11 cleanliness standards for optimal surface prep.

- Repaired damaged areas using Belzona 111 for enhanced durability.

- Applied 2 coats of Belzona 1341N to all prepped and restored surfaces.

- Conducted inspection and touch-ups to ensure long-term performance.

Results & Benefits

✔ Extended service life of tanks with durable protective coatings.

✔ Improved structural integrity through advanced surface repairs.

✔ Ensured continued operational efficiency with minimal downtime.

Abrasive Blast

City Brewery • Memphis, TN

Beverage Manufacturing

Project Overview: Abrasive blast and re-line the interior of 9 fermenter tanks with Munkadur GL.

Our Clients